Safety barriers are an integral part of our daily lives on the road. Yet, despite encountering them every day, we often overlook their significance. Due to their longstanding presence over the years, we sometimes underestimate the safety they provide to every road user.

What is a Safety Barrier?

Commonly known as safety barriers, restraint devices, guardrails, or bertrames, safety barriers are installed along roadways to reduce the severity of road accidents. While their primary objective is to stop vehicles from leaving the road, these vehicle safety devices must deform correctly to absorb the impact and not exacerbate injuries to vehicle occupants in a collision.

At Transpolis, we understand and appreciate the value of safety barriers. With nearly 30 years of experience, Transpolis conducts real-world tests on various types of safety barriers and evaluates them to meet different standards. We specialize in crash tests for road equipment, including safety barriers for roads, shock attenuators, GBA concrete blocks, motorcycle safety barriers, and more. Explore our expertise and behind-the-scenes look at crash tests.

What are the different types of Safety Barriers?

Second to the French Syndicate of Road Equipment (SER), safety barriers cover 120,000 km in France, accounting for 12% of the road network. The installation of safety barriers is not arbitrary : based on the location, environment, hazards, and road users, road safety devices installed meet various criterias.

Metal Safety Barrier

The most common on French roads and highways for over 40 years, the metal safety barrier is the benchmark protection system for vehicles. Offering the highest level of performance, it deforms in the event of a vehicle leaving the road, absorbing some of the impact and redirecting the vehicle.

Metal safety barriers, made of galvanized steel, line the roadside and come in various forms. However, they share a common base: they consist of a sliding element (the long part of the barrier), spacers, and supports, spaced approximately every 4 meters or more (gs2 or gs4 barrier depending on the spacing of the supports). The lifespan of a steel barrier is 30 to 50 years, and the deterioration of the steel’s appearance (rust) does not affect the barrier’s performance. Moreover, in the event of an accident, replacing part of the barrier requires straightforward handling.

Wood Safety Barrier

Most often, the installation of a wooden safety barrier is for aesthetic purposes. Some municipalities aim to preserve the visual environment and prefer this type of barrier because only the wooden part is visible. This type of barrier also comes in various forms: smooth barriers consist of one or two logs and may or may not include a motorcycle screen.

The lifespan of a wooden barrier is shorter than that of metal barriers: between 20 and 30 years, depending on the treatment applied to the wood. In the event of damage following an accident, replacing part of the barrier requires simple handling.

Concrete Adhesive Barrier

Concrete barriers are often installed on central reservations because in the event of a collision, they do not protrude into the other lane. These road safety devices are used in two forms:

- They are directly applied as blocks during temporary traffic management, works, or protection against embankment or landslide.

- Extradited concrete refers to concrete barriers that are directly poured on-site and continuously. This solution is more expensive but guarantees effectiveness.

Concrete barriers are part of the highway environment as they represent a long-term investment. Indeed, their lifespan exceeds 50 years due to excellent aging.

Leader in road equipment crash tests for 30 years.

Additional protections to Road Safety Barriers

Modular Separators

Road maintenance is customary across all territories. Workers and equipment involved in these tasks, day and night, are exposed to danger. Nowadays, the use of orange cones to delimit a zone is no longer sufficient, which is why various modular lane separators exist. Whether metal or concrete modules, these removable lane dividers are temporarily installed near toll booths and work zones to regulate traffic and provide a safe zone.

Motorcyclist Screen

Motorcyclist protection systems, known as motorcyclist screens, are metal plates installed directly on a metal or wooden barrier. Their goal is to reduce the severity of impact between the motorcyclist and the barrier. With the screen, the motorcyclist does not collide with a support or experience a “guillotine” effect. Instead, the metal screen absorbs part of the impact and redirects the rider’s path to the ground.

Transpolis has participated in studies demonstrating the effectiveness of these motorcyclist screens, showing a significant reduction in the severity of impact.

Safety of Art Structures

Safety barriers for art structures are restraint devices installed on bridges and viaducts. They must be more robust and anchored in concrete to retain vehicles leaving the road. Not only must the device redirect the car, but it must also retain vehicles that collide with it. To match the height of trucks, protective screens are added to stop the vehicle and prevent a fatal fall. There are several categories of art structure barriers depending on the desired level of retention.

Junctions, Ends, and Shock Attenuators

Each safety barrier begins its journey from point A to reach a defined point B. It’s not merely placed in one location but must also harmoniously integrate into its surroundings, meeting both safety and aesthetic imperatives. Barrier ends can be buried in the ground, connected to another barrier (steel, concrete, or wood), or protected by shock attenuators. In each configuration, the chosen option ensures the highest level of safety.

Where using Safety Barriers?

Some road sections have significant accident rates. To counter these risks, it is necessary to implement protection devices for road users. Depending on traffic and the environment, various types of barriers exist to apply road accident safety measures. Thus, Regional and Departmental Directorates collaborate with development companies to implement the best solutions, with the ultimate goal of moving closer to the zero-accident risk.

How can we ensure the performance of these safety barriers?

In order to guarantee the performance of safety barriers, strict standards are in place. These standards are used to assess the quality and reliability of safety. In addition, specialized testing laboratories, like Transpolis, carry out rigorous tests to verify compliance with standards or to assess impact resistance. These quality controls and tests ensure user safety.

How Safety Barriers are tested?

Formerly known as LIER (Laboratoire Inrets d’Equipements Routiers) and with over 30 years of experience, Transpolis has long-standing expertise in road safety testing. With over 30 years of experience, our company specializes in conducting full-scale crash tests on various restraint devices. These comprehensive tests are designed to assess the performance of these devices under real impact conditions. We strive to analyze every aspect of the collision, from impact resistance to structure deformation. Our goal is to ensure that restraint devices meet current regulatory standards while guaranteeing an optimal level of safety for road users.

What are the standards for Safety Barriers?

Safety barrier standards vary from country to country and region to region, but certain international standards are widely recognized.

In Europe

The European standard established since the 2000s is known as EN 1317 and offers several variations depending on the type of road accident safety measures. The different EN 1317 standards present several performance levels based on the main criteria ensuring vehicle retention, namely:

- Retention level,

- Shock severity levels,

- Deformation caused by vehicle intrusion: operating width (W)

Depending on the retention level aimed for, the standard imposes different criteria and means of evaluation.

Abroad

The EN 1317 standard is a reference for many countries beyond the European border. However, each country has its additional standards. In France, for example, NF standards apply to certain product types.

The American AASHTO MASH standard is also a recognized reference applied by many road equipment manufacturers.

AASHTO MASH

AASHTO MASH, short for “Manual for Assessing Safety Hardware” represents a set of rigorous standards and criteria established by the American Association of State Highway and Transportation Officials (AASHTO). These standards are specifically designed to evaluate the safety of road restraint devices such as safety barriers, barriers, and crash attenuation systems. As a recognized reference in the industry, AASHTO MASH aims to ensure that these equipment provide maximum protection to road users in the event of a collision.

Transpolis holds accreditation to the AASHTO MASH standard due to its advanced expertise in road safety testing. With many years of experience and in-depth research, Transpolis is equipped with facilities and resources for tests complying with the rigorous requirements of AASHTO MASH.

COFRAC ISO 17025 accreditation demonstrates Transpolis’s commitment to excellence and safety in the road equipment industry. It provides additional assurance to equipment manufacturers and regulatory authorities of the quality and reliability of devices tested by Transpolis.

Transpolis renews its COFRAC ISO17025 accreditation until 2029.

Barrier restreint levels

We can summarize 4 categories of barrier retention levels, each presenting different levels:

- Temporary safety barrier retention level T

- Normal retention level N

- High retention level (High) H

- Very high retention level H4

Each category presents different levels calculated based on the speed and mass of the propelled vehicle and the angle of impact.

Simulation of Safety Barriers

Simulation and available tools allow for calculating forecast results of full-scale crashes. Meshing technique makes the simulation as precise as possible: from steel screw to the barrier’s component to the propelled vehicle’s characteristics. Some manufacturers use simulation, especially for developing new barriers or when modifying certain components and materials. Moreover, the French standard NF058 allows simulation to certify B or C type connections.

Transpolis has its simulation laboratory, EN 16303 accredited, equipped with advanced modeling and crash test simulation technologies. With our expertise and tools, we can perform road collision simulations and simulate various crash scenarios. Our simulation laboratory enables us to evaluate the performance of vehicles and safety devices in a variety of scenarios, in compliance with regulatory standards such as EN 1317 and AASHTO MASH.

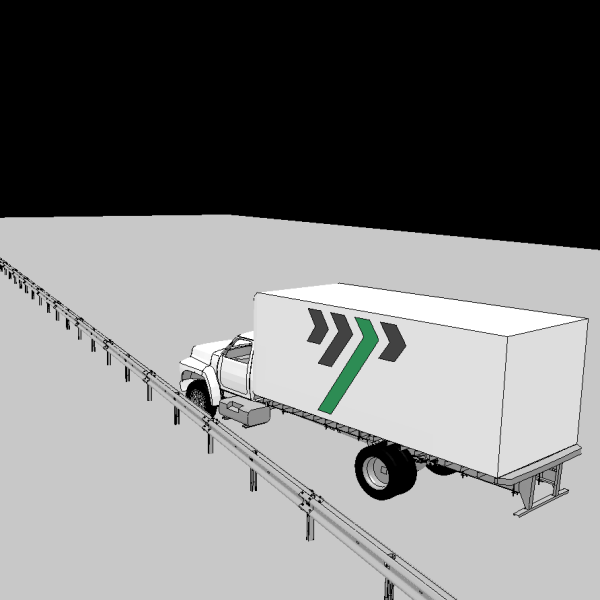

Full-scale crash tests

With different crash zones, we test all types of road safety barriers that meet current standards according to the ISO 17025 standard, for which we are accredited by COFRAC. According to our clients requirements, we set up the vehicle and various infrastructures and tools to ensure an impartial and fair evaluation of the tested devices. At the end of the crash test, our teams draw up a written and video report, which serves as the guardrail’s certification and must then be approved by ASCQUER.

From barrier to hostile vehicle mitigation devices

Transpolis, expert in testing of Safety Barriers and hostile vehicle mitigation devices for 30 years.

We are lalso accredited to evaluate the passive safety of support structures (EN 12767) and conduct crash tests on various safety devices, compliant or not with standards.

Do you have crash tests to perform ? A barrier to test ?

Key Takeaways

Safety barriers are essential elements on our roads, often underestimated but playing a crucial role in reducing accidents. Transpolis, an expert in road equipments crash test for three decades, is a key player in evaluating these safety devices for approval. Compliance with standards, such as EN 1317 and AASHTO MASH, is essential to ensure the effectiveness of equipment. Transpolis offers a full range of services, from simulation to crash tests, to evaluate the performance of road safety devices.